推荐消息更多>>

推荐消息更多>>对于仓泵的类型解析

- 来源:/ 日期:2025-06-05 发布人:创始人

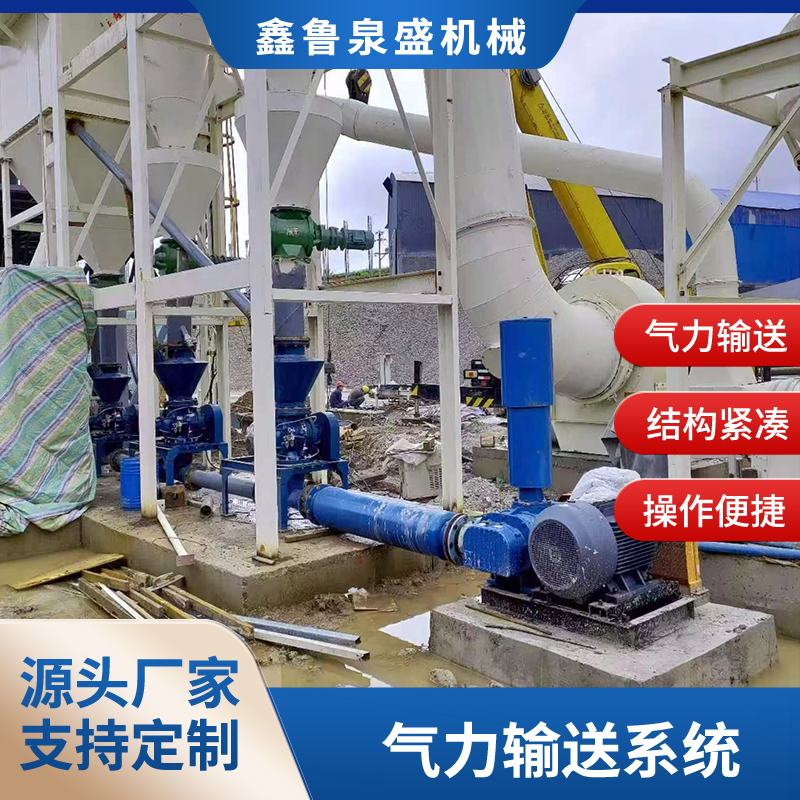

仓泵,作为气力输送系统的核心设备,广泛应用于电力、化工、冶金、建材等领域,其作用是通过压缩空气将粉状或颗粒状物料高效输送至指定位置。根据不同的分类标准,仓泵可划分为多种类型,每种类型在设计原理、适用场景及性能特点上均有显著差异。以下从工作原理、结构特征、输送压力、应用领域等维度,详细解析仓泵的主要类型。

Warehouse pumps, as the core equipment of pneumatic conveying systems, are widely used in fields such as electricity, chemical engineering, metallurgy, and building materials. Their function is to efficiently transport powdered or granular materials to designated locations through compressed air. According to different classification criteria, bin pumps can be divided into multiple types, each with significant differences in design principles, applicable scenarios, and performance characteristics. The following provides a detailed analysis of the main types of bin pumps from dimensions such as working principles, structural characteristics, conveying pressure, and application fields.

按工作原理与结构特征分类,仓泵可分为上引式与下引式两大类。上引式仓泵的进料阀位于设备顶部,排气阀则设置在侧壁或底部。工作时,物料从顶部进入泵体,压缩空气从底部或侧部注入,推动物料向上流动并形成悬浮状态,最终通过输送管道排出。其优势在于进料顺畅、排气彻底,尤其适用于易结块或粘性较大的物料。下引式仓泵的进气口则位于设备底部,物料从顶部加入后,在重力作用下自然堆积于泵体下部。压缩空气从底部进入,将物料吹散并形成流态化,沿管道输送。此类仓泵结构简单、能耗较低,但对物料的流动性要求较高,若物料含水量过高或粒度不均,易导致堵塞。

According to the working principle and structural characteristics, bin pumps can be classified into two categories: upward and downward. The feed valve of the upward suction bin pump is located at the top of the equipment, while the exhaust valve is set on the side wall or bottom. During operation, materials enter the pump body from the top, and compressed air is injected from the bottom or sides to push the materials upward and form a suspended state, ultimately being discharged through the conveying pipeline. Its advantage lies in smooth feeding and thorough exhaust, especially suitable for materials that are prone to clumping or have high viscosity. The inlet of the down drawn bin pump is located at the bottom of the equipment, and after the material is added from the top, it naturally accumulates at the lower part of the pump body under the action of gravity. Compressed air enters from the bottom, blows the material into a fluidized state, and transports it along the pipeline. This type of warehouse pump has a simple structure and low energy consumption, but requires high fluidity of the material. If the material has a high water content or uneven particle size, it is easy to cause blockage.

按输送压力范围分类,仓泵可分为低压、中压与高压三种类型。低压仓泵的输送压力通常在0.1至0.2兆帕之间,适用于短距离、低阻力的输送场景,如厂区内物料转运。其特点是设备体积小、投资成本低,但输送效率有限。中压仓泵的输送压力范围为0.2至0.6兆帕,能够应对中等距离的输送需求,如从仓库到生产车间的物料供应。此类仓泵在能耗与效率之间取得平衡,是应用最广泛的类型。高压仓泵的输送压力可达0.6兆帕以上,专为长距离、高阻力或特殊物料输送而设计,如跨区域粉煤灰输送。其设备强度高、密封性能好,但制造与维护成本也相应增加。

According to the range of conveying pressure, bin pumps can be classified into three types: low pressure, medium pressure, and high pressure. The conveying pressure of low-pressure bin pumps is usually between 0.1 and 0.2 megapascals, suitable for short distance, low resistance conveying scenarios, such as material transfer within the factory area. Its characteristics are small equipment size, low investment cost, but limited conveying efficiency. The delivery pressure range of the medium pressure warehouse pump is 0.2 to 0.6 megapascals, which can meet the demand for medium distance transportation, such as material supply from warehouses to production workshops. This type of warehouse pump achieves a balance between energy consumption and efficiency, and is the most widely used type. The conveying pressure of the high-pressure bin pump can reach over 0.6 megapascals, designed specifically for long-distance, high resistance, or special material conveying, such as cross regional fly ash conveying. Its equipment has high strength and good sealing performance, but the manufacturing and maintenance costs also increase accordingly.

按物料输送方式分类,仓泵可分为连续式与间歇式。连续式仓泵通过恒定的压缩空气流量,实现物料的持续、稳定输送。此类设备适用于大规模、连续性生产场景,如水泥厂生料输送。其优势在于输送效率高、自动化程度高,但对系统稳定性要求严格,一旦出现故障可能导致整个生产线停机。间歇式仓泵则采用周期性进料与输送模式,即每次进料后,通过脉冲式压缩空气将物料一次性排出。此类设备适用于小批量、多品种物料输送,如实验室样品分析。其特点是操作灵活、适应性强,但输送效率相对较低。

According to the material conveying method, warehouse pumps can be classified into continuous and intermittent types. Continuous bin pumps achieve continuous and stable transportation of materials through a constant compressed air flow rate. This type of equipment is suitable for large-scale, continuous production scenarios, such as raw material conveying in cement plants. Its advantages lie in high conveying efficiency and high degree of automation, but it has strict requirements for system stability. Once a fault occurs, it may cause the entire production line to shut down. The intermittent bin pump adopts a periodic feeding and conveying mode, that is, after each feeding, the material is discharged in one go through pulse compressed air. This type of equipment is suitable for small batch and multi variety material transportation, such as laboratory sample analysis. Its characteristics are flexible operation and strong adaptability, but the conveying efficiency is relatively low.

按应用领域与行业特性分类,仓泵可分为通用型与专用型。通用型仓泵设计标准统一,可满足大多数常规物料的输送需求,如粮食、塑料颗粒等。其结构简单、价格亲民,是市场上的主流产品。专用型仓泵则针对特定行业或物料特性进行优化设计,如电力行业的粉煤灰输送仓泵,需具备耐高温、耐磨损等特性;化工行业的原料输送仓泵,则需满足防爆、耐腐蚀等要求。此类设备技术含量高、定制化程度强,通常由专业厂商根据用户需求定制生产。

According to the application field and industry characteristics, warehouse pumps can be classified into universal and specialized types. The universal bin pump has a unified design standard and can meet the transportation needs of most conventional materials, such as grain, plastic pellets, etc. Its structure is simple and its price is affordable, making it the mainstream product in the market. Specialized silo pumps are optimized for specific industries or material characteristics, such as the fly ash conveying silo pump in the power industry, which needs to have high temperature resistance, wear resistance and other characteristics; The raw material conveying bin pumps in the chemical industry need to meet requirements such as explosion prevention and corrosion resistance. This type of equipment has high technological content and strong customization, usually produced by professional manufacturers according to user needs.

仓泵的类型多样,选择时需综合考虑物料特性、输送距离、生产规模及成本预算等因素。随着气力输送技术的不断发展,仓泵的性能将持续优化,应用领域也将进一步拓展。

There are various types of warehouse pumps, and when selecting, factors such as material characteristics, conveying distance, production scale, and cost budget should be comprehensively considered. With the continuous development of pneumatic conveying technology, the performance of bin pumps will continue to be optimized, and their application fields will also be further expanded.

本文由仓泵友情奉献.更多有关的知识请点击:https://www.tokojamtanganunik.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is a friendly contribution from Roots blower For more information, please click: https://www.tokojamtanganunik.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

Related news相关新闻

- 2025-07-03气力输送系统的配套设施都有什么?

- 2025-07-02仓泵 “焕新术”:定期清洗的必要性与实操指南

- 2025-07-01罗茨米兰(中国)齿轮的 “材质密码”:选对材料才能稳 “齿” 前行

- 2025-06-24旋转供料器:运行中的 “小麻烦” 与 “大对策”

- 2025-06-20罗茨米兰(中国):从运转奥秘到全场景应用的深度解码

- 2025-06-18输送界的 “双胞胎”:气力输送系统与仓泵系统的差异密码

- 2025-06-17气力输送的 “动力心脏”:罗茨米兰(中国)的核心使命

- 2025-06-16气力输送系统在各行业物料运输中的广泛应用

- 2025-06-14带你了解罗茨米兰(中国)转子热膨胀控制技术

- 2025-06-13仓泵气力输送技术:高效环保的物料输送解决方案

扫码微信沟通

扫码微信沟通